The automotive industry is seeing a dramatic shift in manufacturing processes, which is spearheaded by generative AI. This powerful technology is helping automobile companies in R&D, supply chain resilience, battery performance, sustainability, and urban mobility.

Generative AI in automotive industry provides more effective, value-driven, and personalized experiences for both manufacturers and customers. This state-of-the-art technology uses advanced AI algorithms to create new designs and develop AI-powered automotive solutions.

With generative AI development, automotive companies can accelerate manufacturing using AI-assisted vehicle prototypes. Moreover, GenAI in vehicle development reduces equipment costs, increases automation, and improves in-car entertainment for enhanced customer experience.

If we talk about the figures, the worldwide generative AI market in the automotive sector was valued at $480.22 million in 2024 and is anticipated to reach approximately $3,900.03 million by 2034. So, industry leaders have massive opportunities to drive measurable results across the entire value chain with intelligent, secure, and cost-effective solutions.

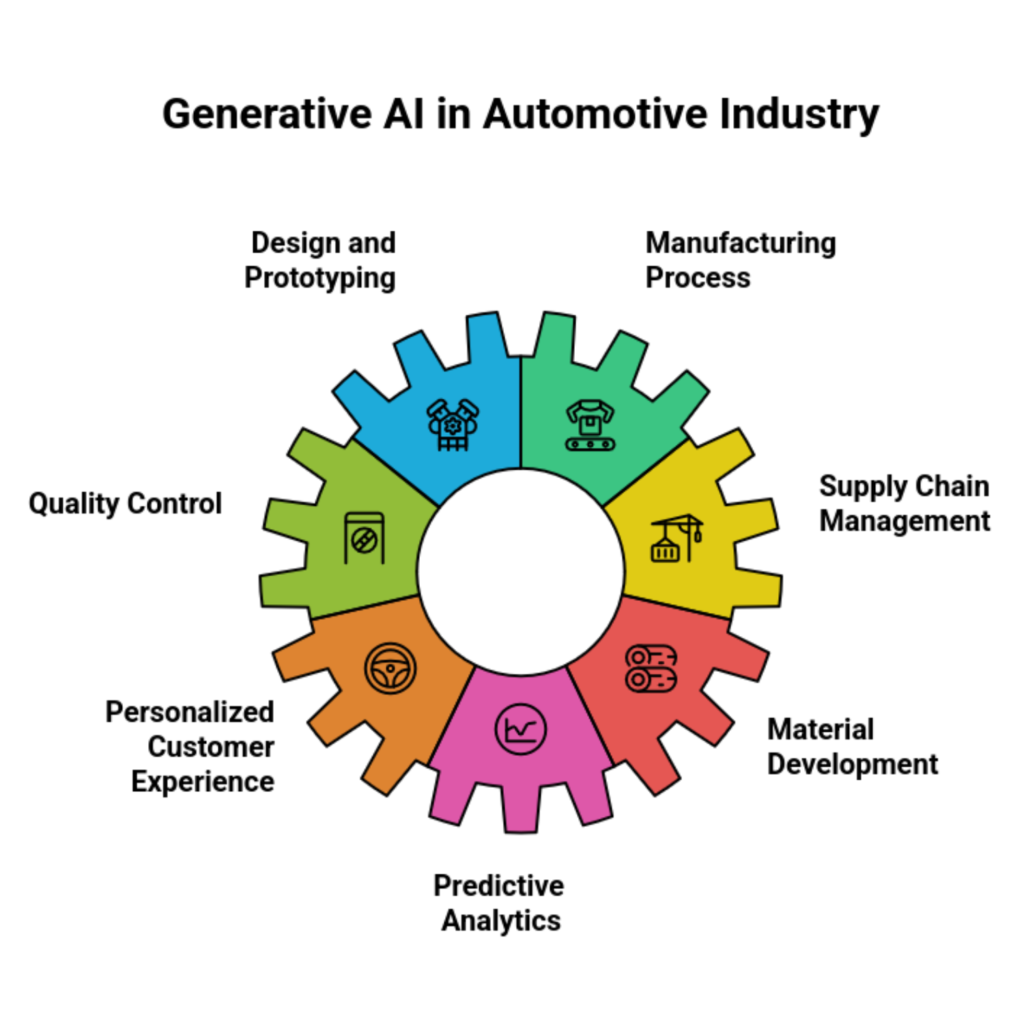

Key Benefits of Generative AI in Automotive Industry

Generative AI in automotive manufacturing offers distinct, goal-driven advantages. It revolutionizes several components, from design, manufacturing, and quality assurance to AI-led material development. With that being said, let’s look at the essential advantages of Generative AI for the automotive industry:

-

Generative AI in Automotive Design and Prototyping

Generative AI uses various input parameters like materials, designs, and constraints to build multiple variations and prototypes. Additionally, generative AI in automotive prototyping offers optimized shapes that reduce material usage to maintain a lightweight design. Apart from that, GenAI models simulate airflow patterns to enhance fuel efficiency.

-

Seamless Automotive Manufacturing Process

Generative AI for automotive process automation examines enormous datasets to improve process efficiency. It detects faults and minimizes material waste to achieve sustainable production. GenAI also helps with predictive maintenance by reducing downtime and anticipating equipment failures beforehand.

-

GenAI-Driven Quality Control

GenAI for automotive quality control can quickly identify defects with more precision than quality analysts. This helps reduce costly recalls and ensure high-quality vehicle components. Moreover, advanced AI algorithms speed up production cycles and reduce the cost of materials, time, and manual labor spent on redoing work.

-

Optimized Supply Chain Management

Automotive companies can take the help of a Generative AI development company to build GenAI models that can analyze historical sales data and market trends to predict supply-and-demand scenarios. This helps to improve inventory inaccuracy and mitigate disruptions using big data analytics. Moreover, generative AI in supply chain systems helps avoid understocking or overstocking issues with replenishment strategies.

-

Personalized Customer Experience

Generative AI in automotive industry helps create personalized content, such as images, videos, and messages, so that customers can feel they are getting one-on-one solutions. GenAI can analyze an individual’s driving behaviors and emotional cues to deliver personalized recommendations and reduce functional silos.

-

GenAI-Powered Vehicle Material Development

Using generative AI in automotive parts production can be a catalyst for designing future-ready vehicle parts and components. It can identify lightweight, durable, and sustainable materials for manufacturing that improve performance and meet environmental standards.

The best aspect of GenAI in automotive manufacturing is that it can build lifelike 3D vehicle models from minimal inputs and sketches. This speeds up the development procedure and assists firms in fulfilling customer demands.

-

GenAI for Predictive Analytics

GenAI models can detect anomalies that deviate from normal driving behaviors. They examine real-time data from sensors to predict market shifts and adapt accordingly. This helps to discover potential hazards, identify system failures, and secure the functioning of autonomous vehicles.

Early-Stage Applications of Generative AI in Automotive Manufacturing

The early interest use cases of generative AI in automotive are massive with research and development, Advanced Driver Assistance Systems (ADAS), and in-car infotainment. It provides business leaders the chance to get a competitive edge. However, they need to have strategic plans along with artificial intelligence consulting.

Original equipment manufacturers (OEMs) have already started to work on some use cases. They use GenAI’s capability to process vast amounts of data and provide contextual intelligence. Let’s check the use of generative AI for the automotive industry:

-

Advanced Driver Assistance Systems (ADAS)

Software-led features are increasing, and ample opportunities exist to simulate test environments. Generative AI for automotive production systems can create test cases for diverse scenarios that can’t be tested on physical vehicles.

Furthermore, generative AI in automotive helps with ADAS through sensor fusion. It also improves object recognition accuracy and allows adaptive responses.

Generative AI in Improving ADAS Performance

- Increased road safety

- Reduced accident risks

- Lane detection

- Collision avoidance

- Parking assistance

-

GenAI for Research and Development

Generative AI in vehicle development could suggest advanced design ideas based on categories such as vehicle construction, lightweight components, durability, costs, etc. This would help design engineers select the most suitable design for development.

Advantages of GenAI in R&D

- Shortened vehicle development lifecycle

- Reduced R&D costs

- Test countless iterations virtually

- Simulations and evaluation

- Improved design suggestions

-

In-Car Driving Assistant Powered by Generative AI

GenAI can be an interactive in-car driving assistant that enhances the user experience. It can analyze drivers’ behaviors and perform tasks like controlling the A/C and playing music hands-free. Moreover, generative AI for automotive innovation can be a lifesaver by identifying a dozing or intoxicated driver and automatically applying the brakes.

Generative AI Advantages for In-Car Driving Assistant

- Voice-enabled navigation

- Intelligent virtual assistant

- Real-time diagnostics

- Map Generation

- Improved journey planning

High-Impact Generative AI Use Cases in Automotive Industry

As stated earlier, some original equipment manufacturers (OEMs) have already started implementing generative AI in automotive manufacturing. Therefore, you must not leave behind in the race. Generative AI in manufacturing design will benefit every aspect of vehicle prototyping, predictive equipment maintenance, or diagnostics. Let’s see how businesses are leveraging GenAI to their advantage.

-

Voice-Enabled Virtual Assistant

GenAI in car manufacturing can help create an intelligent virtual assistant that can easily comprehend human commands using natural language processing. These assistants can converse and respond to voice commands, provide valuable information, and control certain vehicle functions.

-

Generative AI in Automotive Manufacturing For Personalization

To provide drivers with enhanced personalization, GenAI can examine driver’s behaviors and environmental conditions. Additionally, the automotive industry AI transformation can offer various customization suggestions, such as correct/incorrect sitting positions, music preferences, automatic temperature control, etc.

-

Intelligent Routing and Navigation using GenAI

AI-powered automotive solutions can provide smart routing and navigation by accessing real-time traffic data and past driving patterns. In traffic jams, drivers can reroute their travel destinations, saving time and fuel.

-

Estimate Battery’s State of Health (SoH)

GenAI can examine important battery data like voltage, temperature, and current and predict charge cycles to extend battery lifespans with improved data analytics. This helps with battery maintenance and replacement.

-

Object Detection and Recognition

Custom GenAI solutions for car manufacturing enhance autonomous navigation precisely by detecting objects, pedestrians, vehicles, and road obstacles in different environmental conditions.

-

Semantic Segmentation through GenAI

AI-based automotive manufacturing solutions can segment road scenes, such as lanes, sidewalks, and traffic signs, to improve the performance of ADAS systems in complex traffic scenarios.

-

Generative AI for Demand Forecasting

GenAI helps predict market demand fluctuations, which allows OEMs to plan production schedules efficiently. This helps in avoiding overproduction or shortages of automotive manufacturing parts.

-

GenAI for Crash Testing

One of the significant use cases of generative AI in automobile manufacturing is that it can create realistic virtual crash circumstances to test a vehicle’s durability and safety. GenAI can stimulate various collision scenarios to improve driver safety.

-

Provides Contextual Information

Generative AI can examine sensor data, LIDAR scans, GPS, and camera feeds to comprehend the scene and bring out important contextual information. Gen AI models can learn from various data sources to assess traffic patterns, signage, and landmarks.

-

Generative AI for Inventory Management in Manufacturing

GenAI solutions for automotive factory management also optimize dealership inventories by predicting vehicle demand and making sure stocks are available based on customer experience and preferences.

-

After-sale Service and Support

GenAI models for automotive manufacturing enhance after-sale customer support by predicting service requirements and delivering personalized maintenance solutions. Additionally, AI models can automatically resolve issues and ensure a faster response time.

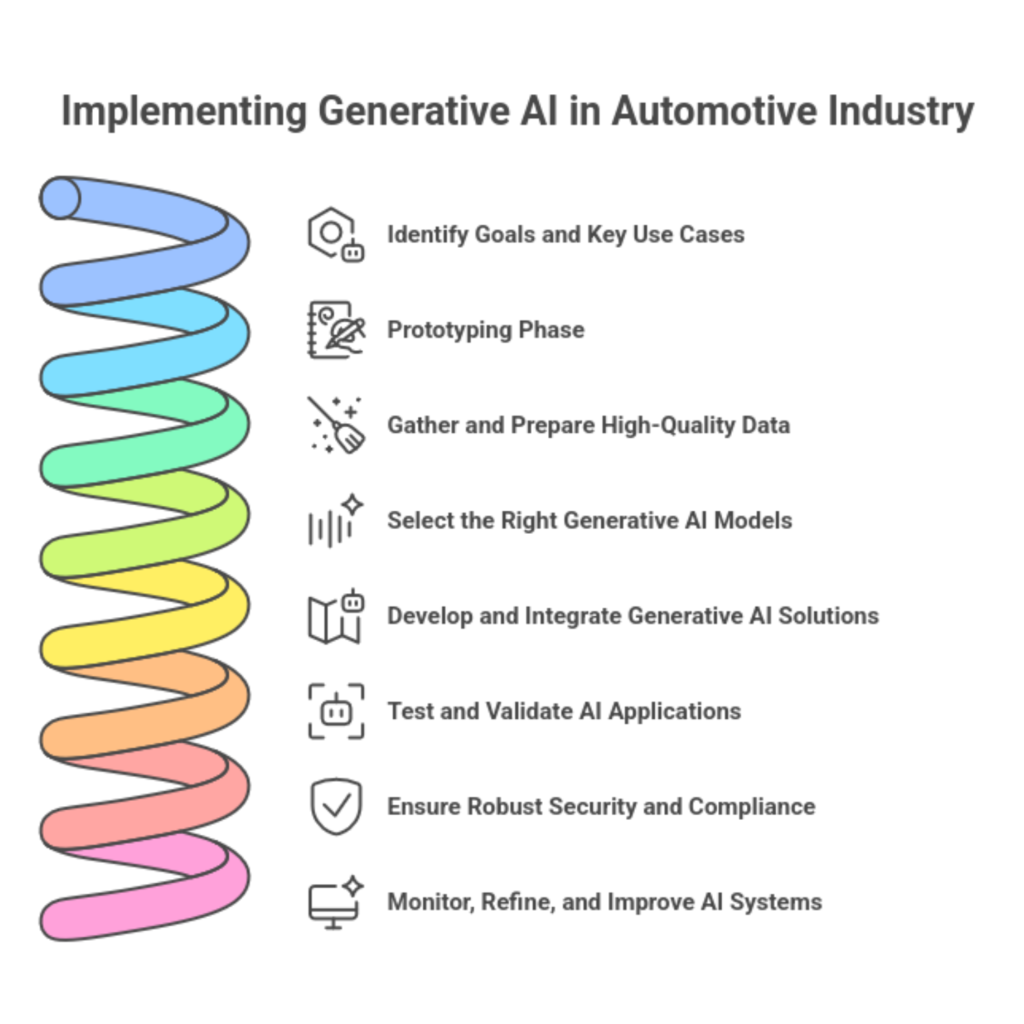

How to Implement Generative AI in Automotive Industry?

The emergence of top-performing generative AI models (GPT-4, DALL·E, StyleGAN, etc.) has made it clear that GenAI is here for the long run. With careful planning, dedication, and a holistic approach, businesses can implement this GenAI in automotive manufacturing.

Business owners must take assistance from a skilled Generative AI software development company to successfully implement innovative AI solutions that drive efficiency, automation, and business growth.

Now, let’s look at the step-by-step process for GenAI implementation.

-

Identify Goals and Key Use Cases

The first step in implementing generative AI in automotive manufacturing is to determine the goals you want to achieve with this technology. These could range from material design improvements to supply chain management to customer enhancements.

You can hire a generative AI company to help identify key use cases in the automotive sector. They will examine potential use cases where AI transformation services can offer great value, like predictive maintenance, NLP development, generative design for vehicle parts, or supply chain optimization.

-

Prototyping Phase

Like any software development stage, implementing generative AI requires product validation. To validate the product, your hired generative AI developers will build a prototype AI model to assess its feasibility, functionality, and performance. This initial version will be rigorously tested to ensure it meets the desired objectives, aligns with business goals, and performs effectively under real-world conditions.

This procedure may include experimenting with various algorithms, datasets, and AI models until they find the best solution. Prototyping helps get feedback from initial users and identify loopholes early, which assists in refining the generative AI model.

-

Gather and Prepare High-Quality Data

Once the prototype is developed, relevant structured and unstructured data is collected to align with the selected use case. Your chosen GenAI services provider will collect data from reliable and credible resources. This ensures a comprehensive dataset to enhance model performance and minimize biases.

The next step focuses on data cleaning. It helps to remove duplicate data, fill gaps, and verify inaccuracies to maintain superior quality. Your GenAI experts will use modern tools for precision-driven data labeling. Once that is completed, ethical guidelines and legal regulations are followed. Finally, GenAI developers will split the dataset into categories like training, validation, and testing subsets.

-

Select the Right Generative AI Models for Automotive Manufacturing

Now, your team will comprehend your chosen use case, whether you want to build an AI model for parts design, text, image, or video generation. Then, based on your business requirements, they select the most suitable model type, such as pre-trained, fine-tuned, or custom models.

After that, GenAI experts examine the AI model’s performance metrics based on accuracy, quality, and scalability to ensure it meets the desired outcomes.

-

Develop and Integrate Generative AI Solutions for Automotive Industry

In this phase, your hired team builds scalable APIs that integrate seamlessly with existing systems. Your Generative AI development partner fine-tunes the AI models to achieve optimal performance and accuracy.

Afterward, they embed the AI solutions into workflows or applications, maintaining a minimalistic design to align with customer demands.

GenAI professionals continuously monitor and track the AI model’s performance, implementing iterative improvements as needed to accommodate sudden changes or evolving requirements.

-

Test and Validate AI Applications

Testing is crucial for any application to establish KPIs, response time, and authenticity.

A company with expertise in machine learning development services can conduct unit testing to verify the correctness of specific elements. They validate the GenAI model using proof-of-concept(POC) in real-world scenarios to test features.

Moreover, with load testing, they can gauge if the GenAI model for the manufacturing industry works fine under heavy usage. Afterward, they also perform security testing to identify vulnerabilities and ensure safety.

-

Ensure Robust Security and Compliance

Generative AI in the automotive industry processes critical data in transit and at rest, making robust encryption methods like AES, DES, and SSL/TLS essential. A leading generative AI development company enforces strict access controls for sensitive data and systems. Generative AI experts adhere to global privacy standards such as GDPR, HIPAA, and CCPA to ensure full compliance.

They conduct regular audits and compliance checks to uphold the integrity of the GenAI models and applications. Developers provide detailed logs, enabling quick incident tracing and response to address any potential issues efficiently.

-

Monitor, Refine, and Improve AI Systems

The AI integration service utilizes various tools to monitor performance, latency, and usage effectively. The team collects user feedback and stakeholders’ inputs to identify pain points and evaluate model performance against established benchmarks.

AI developers leverage updated datasets to enhance model accuracy and deploy automated monitoring systems to detect anomalies and minimize downtime. They continuously improve AI systems by incorporating updates and optimizations to ensure peak efficiency and reliability.

Cost of Deploying Generative AI in Automotive Industry

Implementing generative AI in manufacturing involves various costs that can vary significantly based on the project’s scope, complexity, and specific requirements. Key factors influencing these costs include:

-

Development and Integration

Building a custom generative AI solution for automotive can be a substantial investment. The implementation costs can range from $30,000 to $100,000 or more.

-

Data Preparation and Management

Collecting, cleaning, and managing data for AI training adds to the overall expenses. Costs can vary widely depending on data volume and complexity.

-

Computational Resources

Training and deploying AI models require significant computational power through on-premises hardware or cloud services. Depending on the chosen infrastructure, expenses can range from $10,000 to $50,000 or more.

-

Maintenance and Support

Ongoing maintenance, updates, and support are essential to ensure the AI system’s optimal performance, with annual costs varying based on system complexity and support requirements.

| Basic GenAI Applications | $20,000 to $70,000 |

| Advanced GenAI Solutions | $70,000 and $150,000 |

It’s important to note that these figures are approximate and can vary based on specific project needs, the scale of implementation, and the choice between developing custom solutions or utilizing existing platforms.

The Future of Generative AI in Automotive Manufacturing

As generative AI evolves and continues to get more traction and accessibility, it will discover uncharted territories. Let’s look at the future trends of GenAI in automotive that can significantly impact the industry:

-

GenAI-Powered Autonomous Vehicles

Generative AI will analyze extensive sensor data and images to train and enable self-driving algorithms. The GenAI can quickly learn from multiple scenarios and adapt accordingly. It can forecast road perils and ensure a safer driver experience.

-

Immersive In-Car Entertainment

Generative AI can be utilized to create interactive and immersive entertainment experiences for passengers and drivers. A virtual reality environment can instantly adjust to user’s moods, trends, and patterns. Manufacturing companies can use this data to showcase personalized content according to their demographics.

-

Smart Mobility Solutions

Generative AI for automotive engineering will help improve smart mobility solutions, explicitly reducing vehicle accidents and fatalities. It assists in real-time timetabling, route optimization, and digital ticketing. The on-demand driverless car can arrive at your door, match customer profiles according to their profiles, and optimize traffic flows.

-

Vehicle-to-Everything (V2X) Communication

GenAI can examine sensor data that allows vehicles to interact efficiently with each other. It will also investigate surrounding vehicles and infrastructure elements, such as traffic lights and pedestrians’ movements, to make informed decisions. Gen AI in V2X communication improves traffic flow, environmental sustainability, and productivity.

How SparxIT Empowers GenAI in the Automotive Sector

SparxIT utilizes Generative AI to help the automotive industry with innovation-intensive and goal-driven solutions. We are experts in AI chatbot development, rapid prototyping, and generating vehicle designs using GenAI.

We develop GenAI automotive solutions according to clients’ needs. Our developers have the expertise to build advanced GenAI models that can analyze sensor data to predict manufacturing faults and inefficiencies while reducing downtime. With AI-driven personalization, we improve user experiences through customized in-car systems and interfaces.

SparxIT also provides custom AI solutions for enterprises, advanced simulations, and digital twins to facilitate manufacturing and ensure precision and cost-effectiveness. By implementing generative AI, SparxIT helps automotive companies stay ahead in the evolving market.

Partner with Experts

Frequently Asked Questions

What are the key benefits of using generative AI in automotive production?

GenAI in automotive production helps with R&D, real-time inventory tracking, material management, cost reduction, and the development of autonomous vehicles.

How does AI improve quality control in automotive manufacturing processes?

AI-powered systems use computer vision and machine learning to examine images of products and identify defects. Moreover, AI algorithms can predict equipment failure and automate routine inspection.

Can generative AI help reduce costs in automotive manufacturing?

Definitely! GenAI reduces costs by automating complex tasks. For example, a chatbot can address multiple queries quickly, industrial robots can help manage inventory levels, etc.

How can generative AI optimize automotive manufacturing processes?

Generative AI creates multiple design variations and generates realistic test scenarios to simulate autonomous driving. AI models optimize components like suspension systems, engine parts, and HVAC systems to improve durability.

What are the challenges of integrating generative AI into automotive manufacturing?

Some critical challenges of implementing Generative AI solutions include complex data quality, regulatory compliance, infrastructure demands, skills gaps, and integration with existing systems.