With a rise in higher consumption needs, the manufacturing sector is aiming to achieve exponential growth to meet inflated demand across the globe. To achieve this milestone, organizations are investing in technological enhancements to improve their operational performance and deliver better and faster results. These tech upgrades come with certain data vulnerabilities that make your systems prone to the complexities of cyber threats.

This being said, companies need to be more vigilantly involved in data protection and management practices, as the interconnectivity of modern systems and networks can be easily accessed by cyber criminals today. A report by EC Council also reflects that manufacturing is among the most vulnerable industries to cyberattacks in the modern day. Hence, it is critically important for enterprises to safeguard their operations with advanced cybersecurity solutions.

With an increased focus on data security measures in the digital age, this blog explores how your enterprise can outpace cybercrime by investing in the best practices involved in manufacturing cybersecurity. It also discusses the various challenges and solutions in this direction, along with presenting a detailed roadmap that enterprises can adopt for securing their enterprise operations.

Why is the Manufacturing Sector Becoming a Prime Target for Cybercriminals?

As leading manufacturing enterprises focus on integrating information technology (IT) and operational technologies (OT) to enhance their business operations, the possibility of cyber risk has also increased. As a result, potential cyber risks can impact business performance, leading to missed business opportunities, increased downtime, and reputational and financial losses.

In this light, let’s understand why manufacturing is becoming a primary target for potential cyberattacks:

-

Large Attack Surface

IT and OT leverage advanced features, delivering excellence in modern manufacturing operations, yet their standard safety features are unable to counter advanced cyber risks. As a result, these provide an unsecured large attack surface to cyber criminals, making them vulnerable to critical data risks.

-

Lack of Security Patches

Insufficient updates in redundant legacy platforms weaken the legacy infrastructure, enabling cyberattackers to gain access to enterprise systems by activating ransomware or malware. This can further lead to a stoppage in business functions that directly affect the company’s cost.

-

Risks Associated With The Interconnected Logistics Network

Manufacturing functions are closely interlinked with supply chain networks that help enterprises ensure the distribution of products and services. They assist enterprises in improving digital connectivity and data exchange, but lack the security needed to mitigate the potential cyber risks.

Willing to overcome these hurdles, modern enterprises have prioritized investing in strengthening manufacturing network security by implementing advanced cybersecurity solutions. Moving forward, let’s understand the diverse industry statistics that will help reinforce the need for these solutions in your enterprise.

Key Manufacturing Cybersecurity Data & Insights

Manufacturing is among the fastest-growing sectors globally. It is, nevertheless, a prime target for cyber risks. According to IBM’s X-Force Threat Intelligence Index 2024, manufacturing became the most attacked industry for the third year in a row, beating other services like finance and insurance.

This is a result of various factors, such as growing reliance of manufacturing systems on interconnected digital networks, easy access to systems, and user negligence, which make them susceptible to cyber risks. Let’s look at some concerning cybersecurity industry trends that support this notion.

- 23% of manufacturers experience cyberattacks daily, while 40% face weekly breaches.

- According to the IBM Cost of a Data Breach Report (2023), the average cost of a manufacturing breach is $4.45 million per incident.

- Basic CCPA and GDPR criteria are not met by 43% of manufacturers.

- 56% of manufacturers lack dedicated cybersecurity staff.

- Manufacturers lose $600 billion a year due to intellectual property theft.

Hence, to safeguard your critical data systems from these evolving threats, we recommend that you adopt a well-defined enterprise digital transformation strategy. This strategy will target building integrated security measures in your system that will automatically assist you in avoiding these critically impactful consequences.

Threat Landscape in Cybersecurity for Manufacturing

The manufacturing sector is a growing domain of production opportunities and supply chain integrations. This expansive space of networking is also an opportunity for hackers to interfere with your data, networks, and systems if left unprotected. Thus, businesses need to be cautious about the threats in the manufacturing cybersecurity landscape.

Let’s take a look at the most common forms of cyber threats, explained below:

-

Ransomware Attacks

This malware blocks access to computer systems, giving cyber criminals the chance to force companies to pay a hefty ransom amount, holding sensitive business information hostage in the process.

-

Phishing & Social Engineering

Phishing attacks commonly trick users into revealing sensitive business information like important file passwords. They rely on social engineering techniques that impersonate a trusted source, mainly on email channels.

-

IP Theft

Intellectual property theft in manufacturing mainly involves theft or unauthorized access to valuable business information that can lead to financial losses or potential operational disruptions.

-

Insider Threats

These threats are from the company’s internal resources, like vendors, employees, and others. It involves stealing sensitive business data for personal financial gain or an agenda.

-

Supply Chain Vulnerabilities

Manufacturing firms are susceptible to operational disruptions in their logistics networks due to their interconnectedness with multiple vendor systems that contribute to supply chain vulnerabilities in general.

These cyber risks comprehensively affect business production and performance, causing downtime, and can lead to financial and reputational losses.

Consequences of Weak Cybersecurity for Manufacturing

Strong cybersecurity practices can protect the enterprise from many negative consequences that businesses must avoid, as they may lead to financial losses for the company. Diving deep into this subject, let’s explore the consequences of incorporating weak cybersecurity practices.

1. Operational Disruptions

- Cyberattacks in the manufacturing industry can halt production and the regular flow of operations, leading to significant monetary losses. It also affects the vendor networks and distribution channels that are interlinked with customer satisfaction.

2. Data Breaches

- Cybersecurity for manufacturers is a significant concern today as it protects enterprises from a data breach. This threat accounts for loss of sensitive business information, leading to financial losses, reputational damage, and legal claims.

3. Reputational Damage

- Reputational damage affects the company’s image, which is associated with its market share and customer trust.

4. Regulatory Non-Compliance

- This implies that businesses can face legal consequences and penalties in case of regulatory non-compliance. Some of the acknowledged regulatory bodies are GDPR, NIST, and CMMC.

5. Intellectual Property Loss

- Intellectual property losses can directly impact the market share and client retention for businesses. Thus, these also increase expenses related to litigation issues and damage control.

To prevent these consequences of cyberattacks, advanced AI solutions in manufacturing cybersecurity help businesses protect their operations and build a strong framework for strengthening the overall security systems adopted by the enterprises.

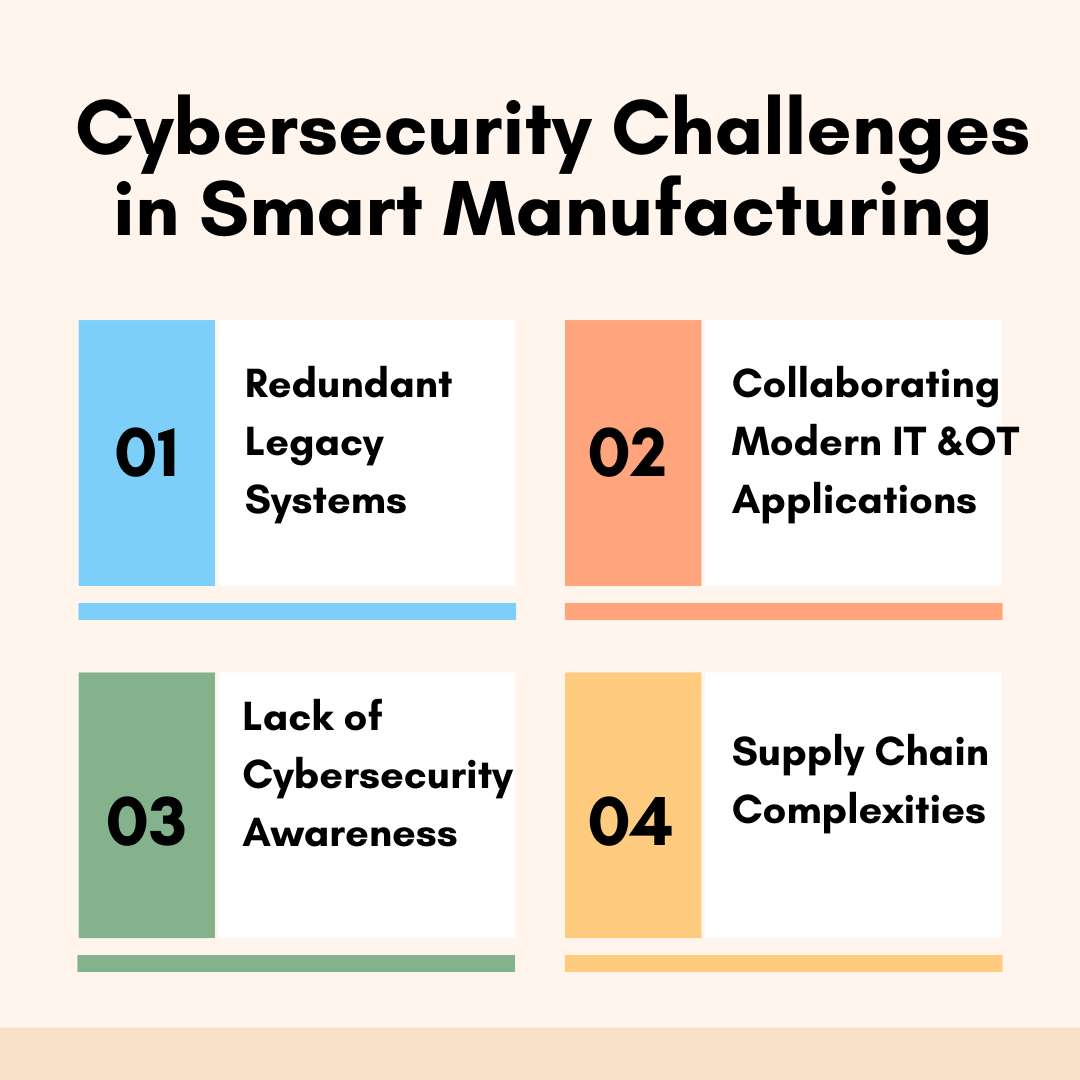

Cybersecurity Challenges in Smart Manufacturing and Their Solutions

Modern manufacturing cybersecurity solutions have proven to be quite successful in increasing the competitiveness of the enterprise systems. Yet, these intelligent practices face some challenges. Let’s study them briefly.

1. Redundant Legacy Systems

Outdated legacy systems lack proper access management, including strong passwords and two-factor authentication, which are meant to protect sensitive business information. This makes them susceptible to cybersecurity risk in manufacturing.

Solutions: Enterprises must focus on phased legacy modernization to help strengthen the network security throughout their systems. Additionally, conducting regular security audits will help strategically improve this process.

2. Collaborating Modern IT & OT Applications

One of the cybersecurity challenges in manufacturing is the integration of modern IT infrastructure with traditional operational technologies, which are an integral part of legacy systems in enterprises. While enhancing data connectivity, they also expose the system to various data vulnerabilities that require cybersecurity monitoring and protection.

Solutions: Elements such as implementing layers of security, unification of safety measures, and collaboration of IT and OT teams will help in this integration. Additionally, it is recommended that manufacturing enterprises invest in credible cybersecurity consulting services to assist this collaboration.

3. Lack of Cybersecurity Awareness

Implementing robust cybersecurity measures in manufacturing is not a standalone role of cybersecurity services. These are integrated along with working on developing employee awareness to avoid the common phishing attacks that come uninvited through email channels.

Solutions: In this regard, investing in regular cybersecurity awareness training can make a huge difference, helping employees stay sharp and avoid these costly errors.

4. Supply Chain Complexities

It is important to consider selecting suppliers and vendors with strong data protection measures, as integrating with them can compromise network security. This signifies the importance of implementing strong security norms, regular vendor checks, and strict access controls that are part of the journey of digital transformation in the supply chain domain.

Solutions: To further enhance their security, enterprises can work on understanding and closely assessing vendor networks and systems for technical loopholes. By performing security testing and imposing strict data sharing measures, they can safeguard their data and information from weak vendor management systems.

Importance of Cybersecurity in Manufacturing Amid Industrial 4.0 Revolution

Leading with future-ready developments associated with smart manufacturing technologies, the industry is undergoing the fourth industrial revolution. This Industrial Revolution 4.0 is distinguished by modern technologies like AI, ML, IoT, and Data Analytics, enabling companies to enhance their operations with an automation-based data-driven system.

These require modern manufacturing cybersecurity measures to serve the following functions:

1. Stakeholder Engagement

- Plays an essential role in implementing cybersecurity measures

- Focuses on quantified risk assessment

- Compliance regulations like NIS2, NIST-800-82, and IEC62443 also help mandate and implement planned cybersecurity measures

2. Building Cybersecurity Awareness

- Considered the primary step in reducing cyber risks

- Includes breaking down data silos

- Improving modern communication approaches in enterprises

- Prioritizing modern cybersecurity agendas

3. Cost Minimization

- Improving productivity and optimizing costs.

- Enables saving on potential financial and reputational losses that are related to compromising manufacturing networks and systems.

4. ROI in Cybersecurity

- Assessing quantified potential risks and financial losses

- Minimizing the impact of downtime to increase ROI in manufacturing cybersecurity

Hence, manufacturers can preserve data integrity, ensure business continuity, and safeguard intellectual property by using cybersecurity in the manufacturing industry.

Considering that Industrial Revolution 4.0 integrates different modern technologies, let’s move forward to see which technologies can pose a threat if they are not protected.

Technologies | Description and Its Associated Risks |

| Wearable sensors |

Associated Risks:

|

| Artificial Intelligence |

Associated Risks:

|

Associated Risks:

| |

Associated Risks:

| |

| IIoT |

Associated Risks:

|

Associated Risks:

| |

| 5G Cellular Networks |

Associated Risks:

|

Best Practices for Shifting from Reactive to Proactive Cybersecurity for Manufacturing

Dealing with these complexities and challenges in smart manufacturing, leading firms have adopted the approach of proactively implementing AI-powered cybersecurity measures that not only mitigate risks but also predict trends and anomalies for more advanced forms of cyber threats.

Moving ahead, let’s look at some of the examples of successful cybersecurity practices in manufacturing.

-

Risk Assessment & Management

Risk assessment primarily involves studying the system vulnerabilities in IT and OT networks to conduct an early risk discovery and plan ahead of time to develop an effective incident response. It helps businesses develop a forward-looking approach that enables them to mitigate potential cyber risks in the future.

-

Implement a Zero-Trust Security Model

A Zero-trust model in manufacturing cybersecurity takes a unified view of the enterprise networks and systems to understand the network segmentation adopted by the firm. Moreover, it also involves conducting security audits to understand the weaker links in the system. This enables planning the implementation of access management for protecting business data and preventing the occurrence of cyber threats.

-

Secure IoT & Industrial Control Systems (ICS)

IoT and ICS systems are effective for performing business operations, yet lack the advanced security features to effectively protect business data. This makes them easily susceptible to cyberattacks. To rectify this situation, leading companies have been encrypting and continuously monitoring these systems for better security.

-

Modernize Legacy Systems

Portrayed as one of the challenges in implementing cybersecurity measures, outdated legacy systems need to be strategically updated phase-by-phase with security patches and modern features. Essentially, take note of smoothly managing business operations in this process to avoid financial losses.

-

Well-Planned Incident Response Strategy

Based on security audits and network segmentation done in various practices, an early risk response can be planned, which may include backups of essential data, and routine testing and monitoring to mitigate critical cyber risks. These plans focus on the swift recovery of the enterprises and minimizing the impact of potential attacks.

Comprehensively, enterprises must be well-prepared to deal with situations of cyber threat in advance by adopting these well-defined practices and measures.

The Role of Regulations & Compliance in Manufacturing Industry Cybersecurity

The role of regulations in safeguarding important information cannot be undermined by businesses, as their avoidance can lead to hefty fines and legal claims against the organizations. So, they must be aware of the stringent frameworks of regulatory bodies to fulfill the standard norms for cybersecurity measures.

In this light, some of the important regulatory institutions are discussed below.

-

NIST Cybersecurity Framework

The National Institute of Standards and Technology Framework helps identify and evaluate significant cyber risks that are prominently occurring in the industry. To mitigate them, NIST provides effective risk management strategies focusing on the protection of IT and OT networks.

-

ISO/IEC 27001 Standard

Associated with ISO 27001, it is a trusted framework for Information Security Management Systems (ISMS). It mainly focuses on risk management and regulatory compliance management.

-

CMMC (Cybersecurity Maturity Model Certification)

CMMC is associated with the Department of Defense (DoD) and helps in securing sensitive defense-related data to meet specific cybersecurity standards.

-

GDPR & Data Protection Laws

It is a globally acknowledged framework for data privacy and management practices. GDPR mainly focuses on protecting customer and employee data and preventing data breach risks.

-

CISA Guidelines (U.S.)

Cybersecurity and Infrastructure Security Agency (CISA) effectively works towards improving threat intelligence practices in manufacturing, along with focusing on incident response plans.

-

IEC 62443

It is an international standard for cybersecurity focused on safeguarding digitally connected manufacturing networks and systems from cyber threats.

How Emerging Technologies Are Transforming the Future of Cybersecurity?

The journey to adopting advanced cyber practices is made possible by leveraging emerging technologies like AI, Gen AI, Blockchain, and Big Data in manufacturing, which can strengthen enterprise networks.

Hence, let’s learn about them in detail.

Modern Technologies | Description |

| AI and Generative AI for Cybersecurity |

|

| Blockchain Development for Secure Supply Chain Management |

|

| Adoption of Secure Access Service Edge (SASE) |

|

| Power of Quantum Computing |

|

| Tech-enabled Edge Computing |

|

Roadmap to Smart and Secure Manufacturing Cybersecurity

Building cyber-resilient practices in industrial manufacturing is important for enterprises to safeguard themselves from the evolving cyber threat landscape. This primarily requires effectively planning network segmentation and working towards strengthening the enterprise application security of enterprise data systems. Additionally, investing in expert red team services can also help improve infrastructure and network security among enterprises.

Key Takeaways:

Here are the key points that can guide enterprises in achieving smart and secure manufacturing practices.

- Integration of IT and OT technologies with built-in security measures is essential to invest in as part of the manufacturing cybersecurity measures.

- Planning a comprehensive tech-enabled incident response plan is a non-negotiable for enterprises to mitigate critical cyber risks.

- Improving factory monitoring in real-time cybersecurity metrics to understand the production levels accurately will help enterprises plan ahead accordingly.

- It is essential to conduct regular vulnerability assessments of vendor systems and legacy software programs. In the long run, enterprises must also focus on legacy software modernization.

- Finally, employee training will help organizations achieve the best results out of this investment by avoiding human error that may compromise data systems.

- Moreover, to achieve secure business systems, enterprises can also trust cybersecurity service providers who can help them in their journey to achieve smart and secure manufacturing practices.

Final Thoughts

As factories are incorporating modern manufacturing technologies, cyber criminals are evolving smartly too. Hence, safeguarding your systems is an imperative measure today for business continuity. To achieve this goal, cybersecurity and manufacturing go hand in hand to develop effective strategies and practices covered in this blog.

Cybersecurity not only protects your systems but also enhances performance through implementing AI in manufacturing. So, enterprises are recommended to take timely, targeted actions to prevent the threat of cyberattacks.

How SparxIT’s Diversified Cybersecurity Solutions Can Assist Modern Manufacturing Businesses?

We help manufacturing enterprises incorporate smart cybersecurity solutions, providing employee training and covering vulnerability assessments from a 360-degree approach. From real-time threat detection to providing suitable incident response plans, we have got you covered.

At SparxIT, you get:

🔹 Full visibility across IT and OT systems.

🔹 Real-time threat detection to stop attacks early.

🔹 AI-powered investigations for faster response times.

🔹 Custom manufacturing software solutions.

🔹 Autonomous threat response to keep operations running smoothly.

Contact us to learn more about our AI-powered cyber services.

Partner with Experts

Frequently Asked Questions

What are the risks of legacy systems in manufacturing cybersecurity?

Outdated legacy systems often lack standard security features in their software programs. They also have trouble integrating with modern technologies, which makes them more susceptible to cyber threats.

What is the cost of a cybersecurity breach in manufacturing?

A cybersecurity breach can be quite costly for manufacturing businesses. As per Statista, the record last year in 2024 marks an average of $5.56 million in losses.

How can manufacturers prepare for a cyber resilience audit?

It can be done through conducting regular risk assessments and strictly verifying third-party accounts like vendor systems.

What are the benefits of investing in cybersecurity for manufacturing companies?

Robust cybersecurity measures help in data protection, regulatory compliance, and preventing financial and reputational losses for manufacturing companies.